Why Carbon Nanotubes?

CNT can change the properties of 70% all materials.

|

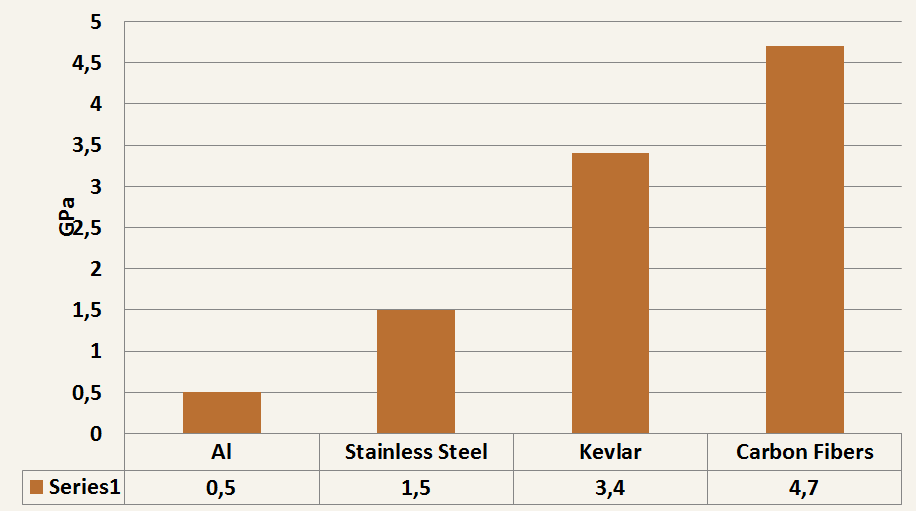

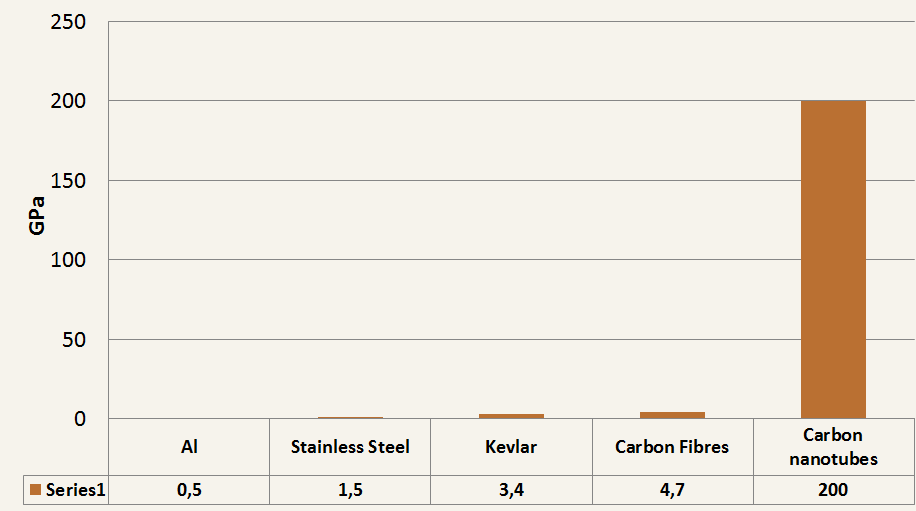

Modulus |

Tensile Strength |

Thermal conductivity | |||

| Al | 70 GPa | 0,5 GPa | 240 W/(mxK) | ||

| Steel | 200 GPa | 1,5 GPa | 400 W/(mxK) | ||

| пёп²п╒ | 1000 GPa | 200 GPa | 4000 W/(mxK) | ||

Tensile strength of egineering materials, GPa.

At the moment the introduction of CNS in metals is possible only in the field of powder metallurgy, thus there is a significant rise in production. Powder metallurgy is not more than 4% of the world market of metal products.

Challenges to the introduction of CNT in the metal melt:

• High chemical inertness of carbon nanotubes

• Low wettability of CNT with metal

• The low thermal stability of CNT

Developed a unique technology that allows to enter CNT directly into the molten metal.

We use a unique method of preparing carbon nanotubes, this method allows significantly improve the properties of modified metals.

Snapshots of the electron microscope: carbon nanotubes modified by technology owned by company's Carbon tech, LLC. CNT introduced directly into the molten aluminum.

The results testing sample of the modified copper (tensile):

|

Options |

Purecopper |

6006* | 6004* | 6008 |

|

Diameter of the samples, п╪п╪ |

8 | 8 | 8 | 8 |

|

Diameter of the samples after testing, п╪п╪ |

7,67 | 6,4 | 7,31 | 2,2 |

|

Modulusof elasticity, GPa |

84 | 83 | 132 | 70 |

|

Maximum load, kgs |

448,4 | 669,2 |

542,9 |

699,3 |

|

Tensile strength, MPa |

87,5 |

130,6 |

105,9 |

136,5 |

|

Yieldstrength, MPa |

50,3 |

40,4 |

59,1 |

48,8 |

|

Proportional limit, MPa |

35,9 |

30,6 |

42,5 |

33,1 |

|

Elongation at break,% |

8,33 |

36,6 |

11,0 |

46,3 |

|

Narrowing at break,% |

8,1 |

36 |

16,5 |

92,4 |

* Samples6006, 6004 and 6008 have different properties due to the different concentration of the modifier.

The results testing sample of the modified aluminum:

|

Б└√ ofsamples |

Modifier type |

CNT concentration, % |

Tensile strength, MPa |

Elongation at break, % |

| 4 |

SWCNT |

0,03* |

71,76 |

30,62 |

| 5 |

SWCNT |

0,12 |

65,99 |

18,22 |

| 6 |

SWCNT |

0,3 |

56,72 |

12,12 |

| 7 |

MWCNT |

0,03 |

62,73 |

16,53 |

| 8 |

MWCNT |

0,12 |

56,14 |

13,36 |

| 9 |

MWCNT |

0,3 |

48,67 |

9,33 |

| 10 |

Controlsample |

- |

37,99 |

5,08 |

*The best result was shown by the sample with the lowest concentration of CNT

EN

EN  RU

RU  CN

CN