The problem wearing of the contact wire.

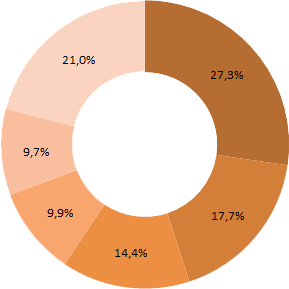

The distribution of damage to the device contact network on elements.

| Kind of damage | |

| Wires | 27,3% |

| Insulators | 17,7% |

| Clamps | 14,4% |

| Air arrows | 9,9% |

| Strings | 9,7% |

| Other | 21% |

Contact wires (CW) is a key element of the contact network. In operation CW is feeling the effects of variations in air temperature, ambient humidity, and other destructive factors. The materials currently used for the manufacture of the CW (copper, copper alloys) has high electrical conductivity, but don’t have sufficient wear resistance. In this regard, a large percentage flaw contact networks falls on CW.

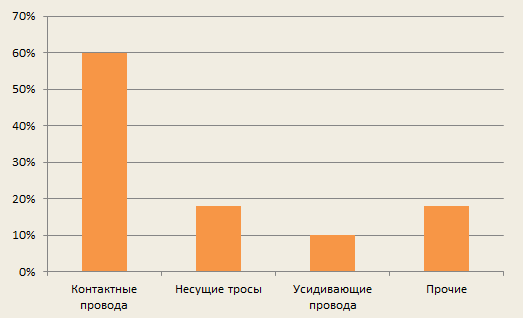

Damage the wires and cables (2010-2014)

The contact wires (CW) are the most damaged element of the contact network (about 60 %), including DC sections - 84,4 %. Burn weld CW was 21% and the cliffs of 12.3% of the total number of damages. These results indicate that, despite the measures taken to improve the reliability of the contact network, the amount of stretch over many years remains approximately at the same level.

Properties that should be possessed by CW.

The main material for the CW - copper, bronze.

High electrical conductivity

Strength

Durability

The minimum cost

Spark erosion resistance

This combination of properties not possessed by any metal and alloy

Our technology allows to solve tasks almost without changing the existing production technology, and to reduce considerably the production costs of the final product.

The problem of wires abrasion for power transmission lines

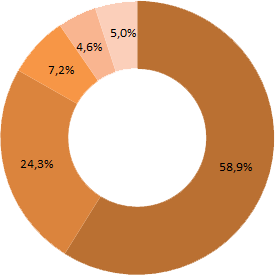

The technical structure of energy consumption in UNEN* according to the results 2012 y.

| Variable (load) losses | 58,9% |

|

The crown effect |

24,3% |

|

Idling transformers |

7,2% |

|

Own needs |

4,6% |

|

Other losses |

5,0% |

Electric grid facilities are aging rapidly. The wear level reaches almost 70%, with 60% of the energy losses in the transmission falls on a wire. An equal challenge is the low mechanical strength of the wires that leads to the cliffs on power lines and reduces the quality of electricity supply.

* Unified national electrical network;

* Loss of energy during transmission due to the occurrence of corona discharge (corona)* Federal Grid Company of Unified Energy System

|

FGCUES * |

|||

|

The total length of the grid, thousand km. |

125,3 | ||

|

Thelevel equipment wear |

57% | ||

|

In operation for over 40 years |

27% | ||

|

Total power loss, billion kWh |

23,7 | ||

|

Total power loss |

4,8% | ||

|

ROSSETI |

|||

|

The total length of the grid, thousand km. |

2000 | ||

|

Thelevel equipment wear |

67% | ||

|

In operation for over 40 years |

7,4% | ||

|

Total power loss, billion kWh |

57,3 | ||

|

Total power loss |

8,9% | ||

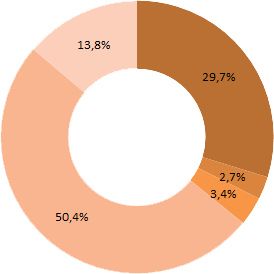

The causes of technological failures in the power grid during the period 2001 – 2012 years.

|

Garland insulators |

29,7% |

| Fittings | 2,7% |

| Pillar | 3,4% |

| Wires | 50,3% |

| Other | 13,8% |

According to over the 11 years of observation of transmission lines, more than half technology failures in the power grid falls on wires. Therefore, improving the reliability of the wires will significantly increase the reliability of networks.

Advantages of new material for power transmission line:

Energy efficiency::

Energy saving:

Comparative characteristics of wires:

| Characteristic |

For use on overhead power lines |

п░п║ 400/51 |

AAAC 455-27 | Accc 430 Brussels |

| Manufacturer | Russia | Russia | Belgium | Belgium |

| Design | Al |

Steel, Al |

Al alloy/Al alloy |

Composite/Al |

|

Cost of the wires, Ths.rub./km |

26,8 | 162,0 | 480,1 | 845,0 |

Using thetechnology of aluminum reinforcement of CNT will be obtained wiresby price30 rub/mwith characteristics not inferior to composite wires of the new generation for 850 rub/m.

EN

EN  RU

RU  CN

CN