The problem of wires abrasion for power transmission lines

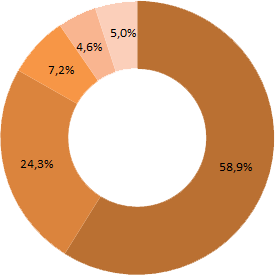

The technical structure of energy consumption in UNEN* according to the results 2012 y.

| Variable (load) losses | 58,9% |

|

The crown effect |

24,3% |

|

Idling transformers |

7,2% |

|

Own needs |

4,6% |

|

Other losses |

5,0% |

Electric grid facilities are aging rapidly. The wear level reaches almost 70%, with 60% of the energy losses in the transmission falls on a wire. An equal challenge is the low mechanical strength of the wires that leads to the cliffs on power lines and reduces the quality of electricity supply.

* Unified national electrical network;

* Loss of energy during transmission due to the occurrence of corona discharge (corona)* Federal Grid Company of Unified Energy System

|

FGCUES * |

|||

|

The total length of the grid, thousand km. |

125,3 | ||

|

Thelevel equipment wear |

57% | ||

|

In operation for over 40 years |

27% | ||

|

Total power loss, billion kWh |

23,7 | ||

|

Total power loss |

4,8% | ||

|

ROSSETI |

|||

|

The total length of the grid, thousand km. |

2000 | ||

|

Thelevel equipment wear |

67% | ||

|

In operation for over 40 years |

7,4% | ||

|

Total power loss, billion kWh |

57,3 | ||

|

Total power loss |

8,9% | ||

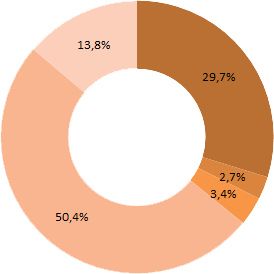

The causes of technological failures in the power grid during the period 2001 – 2012 years.

|

Garland insulators |

29,7% |

| Fittings | 2,7% |

| Pillar | 3,4% |

| Wires | 50,3% |

| Other | 13,8% |

According to over the 11 years of observation of transmission lines, more than half technology failures in the power grid falls on wires. Therefore, improving the reliability of the wires will significantly increase the reliability of networks.

Advantages of new material for power transmission line:

Energy efficiency::

Energy saving:

Comparative characteristics of wires:

| Characteristic |

For use on overhead power lines |

п░п║ 400/51 |

AAAC 455-27 | Accc 430 Brussels |

| Manufacturer | Russia | Russia | Belgium | Belgium |

| Design | Al |

Steel, Al |

Al alloy/Al alloy |

Composite/Al |

|

Cost of the wires, Ths.rub./km |

26,8 | 162,0 | 480,1 | 845,0 |

Using thetechnology of aluminum reinforcement of CNT will be obtained wiresby price30 rub/mwith characteristics not inferior to composite wires of the new generation for 850 rub/m.

EN

EN  RU

RU  CN

CN