The problem wearing of the contact wire.

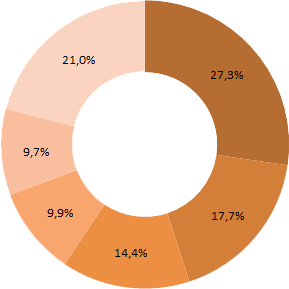

The distribution of damage to the device contact network on elements.

| Kind of damage | |

| Wires | 27,3% |

| Insulators | 17,7% |

| Clamps | 14,4% |

| Air arrows | 9,9% |

| Strings | 9,7% |

| Other | 21% |

Contact wires (CW) is a key element of the contact network. In operation CW is feeling the effects of variations in air temperature, ambient humidity, and other destructive factors. The materials currently used for the manufacture of the CW (copper, copper alloys) has high electrical conductivity, but don’t have sufficient wear resistance. In this regard, a large percentage flaw contact networks falls on CW.

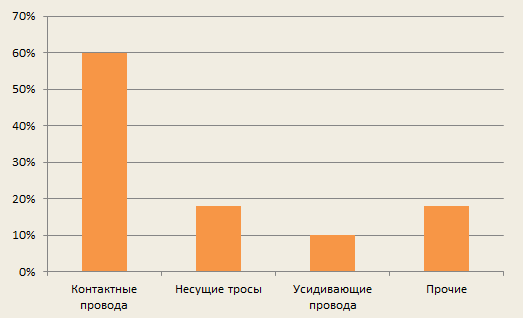

Damage the wires and cables (2010-2014)

The contact wires (CW) are the most damaged element of the contact network (about 60 %), including DC sections - 84,4 %. Burn weld CW was 21% and the cliffs of 12.3% of the total number of damages. These results indicate that, despite the measures taken to improve the reliability of the contact network, the amount of stretch over many years remains approximately at the same level.

Properties that should be possessed by CW.

The main material for the CW - copper, bronze.

High electrical conductivity

Strength

Durability

The minimum cost

Spark erosion resistance

This combination of properties not possessed by any metal and alloy

Our technology allows to solve tasks almost without changing the existing production technology, and to reduce considerably the production costs of the final product.

EN

EN  RU

RU  CN

CN